A report from McKinsey Global Institute highlights the looming challenges facing manufacturers in the United States, including workforce shortages, debt, inflation, and the cost of energy. Improving productivity by focusing on lean manufacturing is one of the primary ways for manufacturers to meet these challenges. Integrating technology and innovative tools has become essential in driving lean initiatives. It is estimated that 98% of manufacturers expect to increase efficiencies with digital technologies. Digital signage is one technology that can significantly enhance lean efforts in manufacturing facilities. It can be leveraged to create a more efficient, responsive, and informed manufacturing environment.

Understanding Lean Manufacturing

To understand how digital signage can enhance lean manufacturing efforts, one must understand what Lean Manufacturing is about.

Lean Manufacturing is a systematic approach that eliminates waste, optimizes productivity, and creates value for customers. It emphasizes continuous improvement, effective inventory management, reducing lead times, eliminating defects, and overall streamlining all operations to enhance competitiveness.

The Role of Digital Signage in Lean Manufacturing

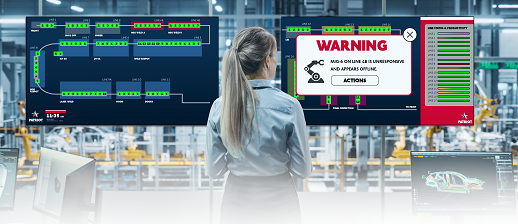

You can eliminate waste by visually sharing important messages and dynamic data across production lines with digital signage. When effectively integrated into manufacturing facilities systems such as Enterprise Resource Planning (ERP), Quality Management Systems (QMS), and Material Requirement Planning (MRP), digital signage can be a powerful tool for implementing and enhancing Lean Manufacturing principles and reducing waste.

Real-time Data Visualization

Real-time data is crucial for decision-making and problem-solving. Digital signage displays can be strategically placed to show key performance indicators (KPIs), idle time caused by equipment, and other relevant real-time data. Employees and managers can quickly make data-driven decisions to address production issues, identify bottlenecks, and monitor progress toward lean goals by providing instant access to this information.

Production Efficiency and Scheduling

Digital signage can clearly and visibly display production schedules and updates. This allows for better coordination among teams and helps promptly identify any deviations from the schedule. It also aids in efficient resource allocation, reducing idle time and improving overall productivity.

SQDC Boards

SQDC boards in manufacturing help enhance safety by highlighting potential hazards, ensuring top-notch quality by tracking defects, optimizing delivery schedules for on-time production, and monitoring costs for efficient budgeting. With real-time visual data, teams can make informed decisions, improve processes, and drive overall performance to new heights.

Work Instructions and Training

Standardizing work processes is essential to reduce variation and increase efficiency. Digital signage can display visual work instructions, safety guidelines, and training materials for workers. This ensures that all employees have easy access to standardized instructions, reducing errors and the time required for training.

Lean Culture Promotion

Creating a lean culture within a manufacturing facility is as important as implementing lean techniques. Digital signage can display lean principles, success stories, and recognition for outstanding contributions. This fosters a culture of continuous improvement and motivates employees to actively participate in lean initiatives.

Visual Management

Lean Manufacturing places great importance on visual management to make processes more transparent and easier to understand. Digital signage can be leveraged to create visual dashboards representing the entire production process, highlighting areas of concern and areas where improvement is needed. This visual representation simplifies decision-making and fosters a shared understanding among teams.

Continuous Improvement

Digital signage can facilitate continuous improvement by displaying employee feedback mechanisms, suggestions, and improvement ideas. These suggestions can be analyzed and integrated into the lean process, ensuring the organization continually evolves to eliminate waste and optimize processes.

Environmental Monitoring

Efficiency in lean manufacturing includes minimizing resource consumption. Digital signage can be used to display real-time energy consumption and environmental data. This enables manufacturers to identify energy-saving opportunities, reducing operational costs and environmental impact.

Practical Implementation

To effectively leverage digital signage for enhancing lean manufacturing efforts, there are some practical steps to consider:

Identify Key Information Needs

Determine the most critical information that needs to be conveyed through digital signage. This may include KPIs, production schedules, safety protocols, and more. Prioritize what should be displayed to avoid information overload.

Strategic Placement

Place digital signage screens at key locations within the facility, where employees can easily view the information. Consider high-traffic areas, workstations, and locations with a high likelihood of bottlenecks or quality issues.

Interactive Touchscreens

Consider using interactive touchscreens for specific applications. These can allow employees to input data, report issues, or access detailed information, creating a more engaged workforce.

Integration with Data Sources

Integrate digital signage systems with your manufacturing data sources. This can include MES (Manufacturing Execution Systems), ERP (Enterprise Resource Planning) systems, and IoT (Internet of Things) devices to ensure that the displayed information is always up-to-date.

Content Management

Have a clear content management strategy in place. Regularly update and customize the content to ensure it remains relevant and useful. Use dynamic templates to facilitate easy updates.

Employee Training

Train your employees on how to use and interpret the information displayed on digital signage screens. This will ensure that the technology is maximally effective in supporting lean initiatives.

Monitor and Adapt

Continuously monitor the impact of digital signage on your lean efforts. Collect employee feedback and make necessary adjustments to improve the system's effectiveness.

Lean Manufacturing is a powerful approach for optimizing manufacturing processes. Still, in today's digital age, harnessing technology to drive these initiatives even further is crucial. Digital signage is an invaluable tool for enhancing lean efforts by providing real-time data, improving communication, promoting a culture of continuous improvement, and increasing overall efficiency. By strategically integrating digital signage into manufacturing facilities, organizations can streamline operations and empower employees with the information and tools they need to pursue lean manufacturing excellence. This way, digital signage becomes essential to a lean organization's journey toward greater competitiveness and success in modern manufacturing.